.png?width=56&name=grey%20hands%20(1).png) Why we are trusted partners

Why we are trusted partners

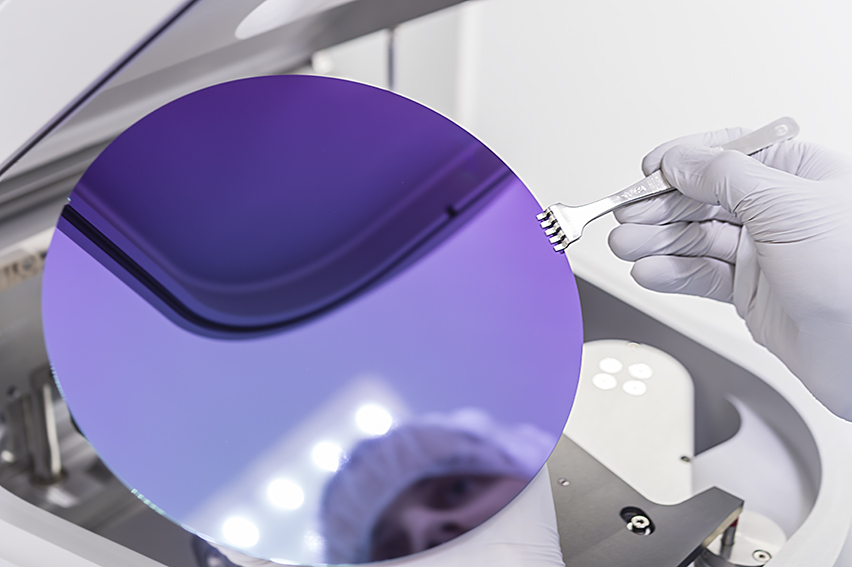

For more than 30 years we have been providing those in industry and academia with plasma etch and deposition systems.

Our parent company, Plasma-Therm, is a global leader in the space, giving us access to world class resources and insights. With our team expertise and advanced equipment, we are the smart choice.

Our know-how

Built on more than 30 years of combined experience and expertise, CORIAL is the technology leader driving innovation in plasma etch and deposition equipment for specialty semiconductor markets.

We invest 15% of our revenues in R&D, in order to provide the most versatile, reliable, and highest-performing etch and deposition systems for specialty semiconductor markets.

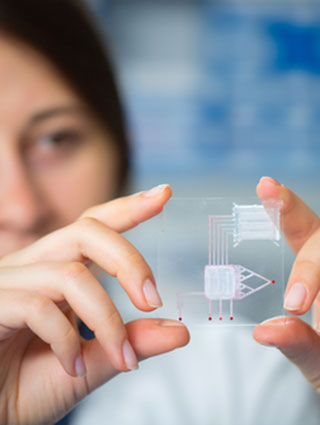

We deliver the only control software that broadens the process capabilities of conventional ICP tools to enable time-multiplexed processes such as the Bosch process, and Atomic Layer Etching (ALE).

Our engineers combine a thorough knowledge of plasma physics and chemistry with rigorous experimental design techniques (D.O.E.) to develop our products and processes.

That technical expertise plus our distribution network enables CORIAL to offer a highly flexible suite of products with low cost of ownership.

At CORIAL, we address a range of end-market applications including MEMS, optoelectronics, failure analysis, power devices, advanced packaging, wireless devices and integrated optics.

Our R&D team continuously develops and fine-tunes the etching and deposition processes that will enable our customers to structure the materials of today and tomorrow.

CORIAL in brief

30

years of customer support

in research institutes, universities,

and fabs

9

specialty semiconductor markets

served by our process solutions