CORIAL announces the availability of glass DRIE process using a new generation of 200 mm ICP-RIE equipment.

CORIAL’s new process for glass DRIE

Glass is an attractive material for MEMS devices, and it is typically used for fabrication of optical microsystems, lenses, waveguides, or biochips.

Its unique properties (optical transparency, mechanical robustness, biological compatibility, electrical resistivity) and its lower cost compared to silicon are welcome advantages for these applications.

Contrary to Si DRIE, which is routinely used to create micro-structures for MEMS manufacturing, one of the main challenges for the wider adoption of glass in the MEMS industry is the ability to create deep structures in this material using dry etch processes.

Etch rate 0.5 µm/min to 1 µm/min

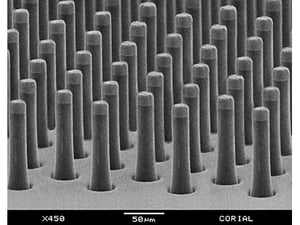

We have developed etch recipes for glass DRIE suited for the MEMS industry, with benefits including high etch rate, superior profile control, smooth surface, excellent selectivity, and anisotropic profile for etch depths greater than 100 µm.

New generation of 200 mm ICP-RIE equipment

Since 2004, CORIAL has offered hardware and process improvements

Glass deep etch on 4″ borofloat wafer

With our latest generation of 200 mm ICP-RIE equipment, not only will new customers benefit from its enlarged process capabilities for deep etching of hard materials, but existing customers can also access this technology through system upgrades.