Light up the world with the ICP-RIE equipment offering industry-leading uniformity and repeatability for PSS applications

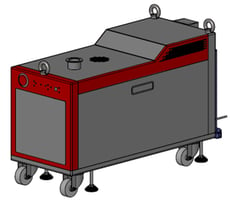

Corial 360IL ICP-RIE etch system in brief in brief

The Corial 360IL is a large area plasma etch system offering high throughput, without compromising process performance or quality.

The 360IL is based on CORIAL’s latest generation ICP (inductively coupled plasma) source. The system features a high-density plasma, 2 MHz ICP RF generator, and state-of-the-art gas injection, allowing fast etch rates and excellent uniformities.

Featuring a vacuum load-lock, the Corial 360IL delivers stable process conditions, short pump cycles and provides the capability to run fluorinated and chlorinated based chemistries on the same tool.

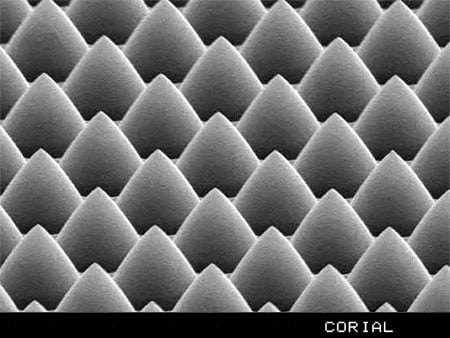

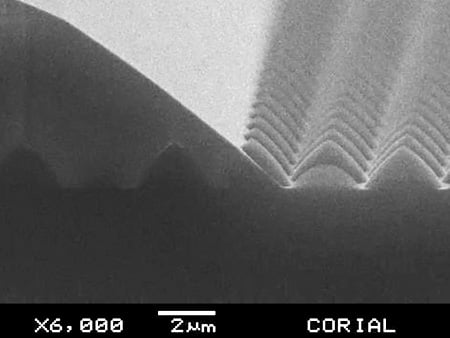

Our PSS processes deliver perfect conical-shaped features, even at the wafer edge, with industry leading uniformity and repeatability.

For MEMS and power devices markets, the Corial 360IL ICP-RIE system is capable of processing a wide range of materials including silicon, oxides, nitrides, and III-V compound semiconductors.

Key benefits

Key benefits

R

PROCESS FLEXIBILITY

The RF match box operating range (from 100 W to 2000 W) supports a wide range of customer applications

The vacuum load lock enables using a combination of fluorinated and chlorinated chemistries in the same tool

R

HIGH ETCH RATE CAPABILITY

Wall temperature > 250°C; ICP max power: 2000 W; RF max power: 1000 W; high efficiency of RF coupling to plasma

Fast and uniform etching: GaAs (500 nm/min), Sapphire (75 nm/min), GaN (200 nm/min) …

R

BEST REPEATABILITY

Load lock for stable and repeatable process conditions

Novel cathode design and efficient helium back side cooling of the shuttle and substrate ensure uniform temperature control (from -50°C) during the etch process

R

EXCELLENT UNIFORMITY

High density plasma enables highly uniform PSS profiles

Optimized gas showerhead with top gas inlets

R

OPTIMIZED LONG-LIFE SHUTTLE

Proprietary quartz shuttle (carrier) design for PSS, with edge effect < 1 mm

Quartz carrier lifetime > 5,000 runs

R

HIGH THROUGHPUT

Large batch capacity: 23 x 2”, 7 x 4”, 3 x 6”

Throughput > 8 WPH for PSS application using 4″ substrates

Related processes

Typical materials that can be processed with the Corial 360IL ICP-RIE system include:

- Silicon

- Oxides: SiO2, Si3N4

- III-V compounds: GaN, AlGaN, InP

The Corial 360IL can serve a variety of applications in specialty semiconductors markets including optoelectronics, MEMS, power devices and many other markets.

Sapphire etch for PSS

Optoelectronics

- Etch rate 75 nm/min

- Uniformity ±2%

- Throughput > 8 wph (4″)

GaN etch for mesa structuring

Optoelectronics

- Etch rate 200 nm/min

- Uniformity ± 3%

- Throughput > 120 wph (2″)

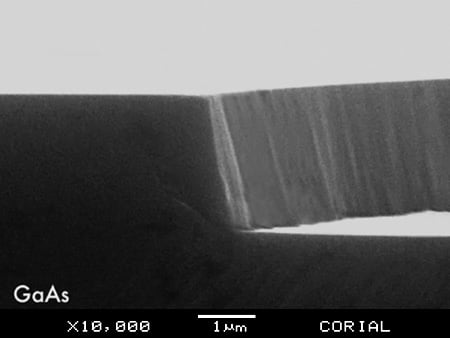

GaAs etch for mesa structuring

Optoelectronics

- Etch rate 500 nm/min

- Etch depth 2 µm

- Uniformity ± 3%

Upgrades

The Corial 360IL ICP-RIE etch system can be thoroughly customized with a wide range of features.

Additional gas inputs

Additional gas inputs (up to 8) for more complex process gas combinations

Wide temperature range cathode

Cathode supports low temperature capability down to -30°C

Variety of pumps

Dry Vacuum pump and TMP pump with varied pumping rate for increased control over the process chamber pressure

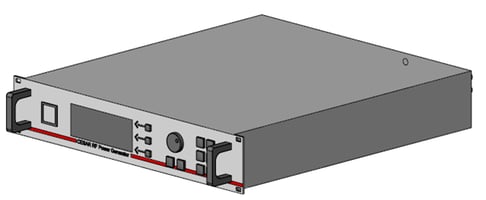

Variety of RF power supplies

Lower output power supplies with automatic matching network.