Production-ready PECVD system for fast and uniform deposition on full 300 mm wafers, or large batch capacity. Typical markets adressed by the Corial D350 PECVD system include optoelectronics, photonics, and MEMS

Corial D350 PECVD system in brief

The Corial D350 PECVD system is designed to produce high-quality, uniform films for photonics, optoelectronics, and MEMS device manufacturing.

The Corial D350 system is based on our unique reactor design. It houses an isothermal, pressurized reactor within a vacuum vessel, which is different from conventional PECVD reactors with heated substrate holders.

Featuring a next-generation gas showerhead and symmetrical pumping, the Corial D350 delivers excellent deposition uniformity for a wide variety of applications.

The Corial D350 PECVD system handles full 300 mm wafers or large batch capacity (27 x 2”), enabling volume production of high-quality films.

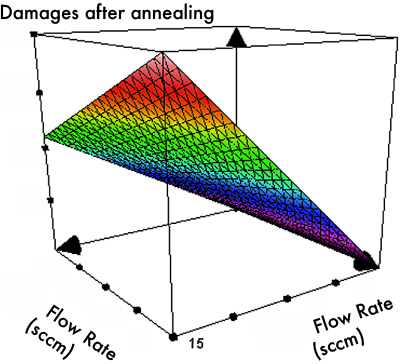

Typical applications for this PECVD system include passivation deposition for optoelectronics, deposition of silicon oxides for photonics, and sacrificial layer deposition for MEMS. Stress control of the films is simplified and optimized on account of the symmetrical design of the reactor.

The Corial D350 system can operate for years without the need for manual cleaning.

Key benefits

Key benefits

R

EXCELLENT UNIFORMITY

Precise and uniform temperature control of the substrate and reactor walls delivers excellent deposition repeatability and uniformity

The pressurized, symmetrically-pumped reactor ensures high-quality films free of pinholes.

R

HIGH DEPOSITION RATES

With its isothermal, pressurized reactor, the Corial D350 rapidly deposits uniform films on wafers up to 300 mm in diameter

Typical performance: SiO2: >500 nm/min; Si3N4: 250 nm/min; SiOCH: 150 nm/min; SiC: 100 nm/min

R

CONTROL OF FILM PROPERTIES

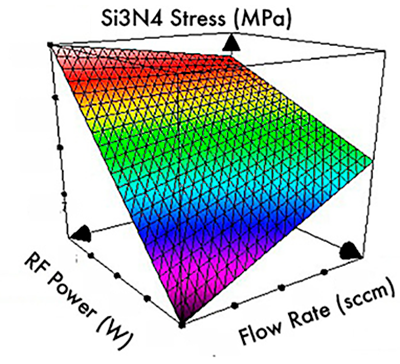

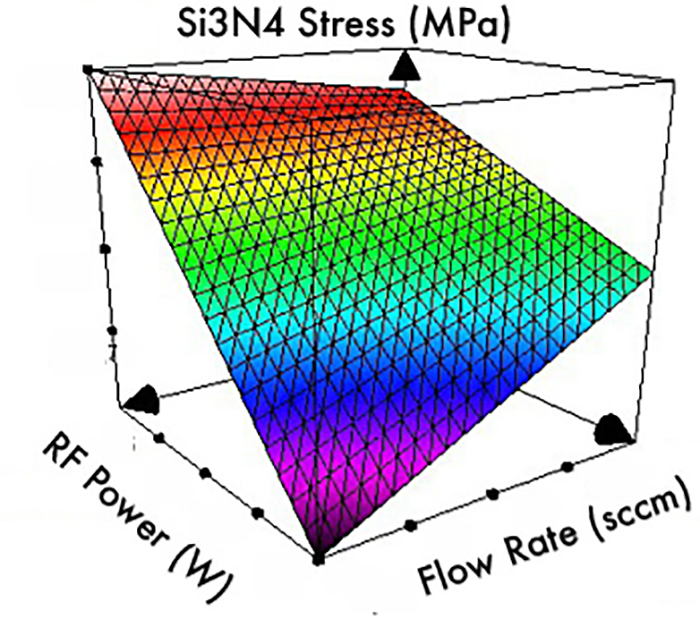

Film stress control is simple to achieve, thanks to the reactor’s symmetrical design

The Corial D350 heating system enables precise control and optimization of refractive index and wet chemical etch rate

R

INCREASED UPTIME

The Corial D350 high temperature, dual pumped configuration enables efficient plasma cleaning at operating temperature, with no corrosion of mechanical parts

No manual cleaning of reactor or vacuum vessel required for many years of operation

Related processes

Typical materials deposited with the Corial D350 PECVD system include silicon-based compounds such as SiO2, Si3N4, SiOCH, SiOF, and aSi-H at high temperature (325°C).

The Corial D350 has been specifically design for production of films for photonics, optoelectronics and MEMS markets.

PECVD of Silicon Nitride (Si3N4) film with tensile stress

MEMS

- Deposition rate 50 nm/min

- Refractive index 1.91

- Stress 220 ± 50

Stress-less deposition of Silicon Nitride (Si3N4) film

MEMS

- Deposition rate 75 nm/min

- Refractive index 1.91

- Stress 0 ± 50 MPa

PECVD of Silicon Nitride (Si3N4) film with compressive stress

MEMS

- Deposition rate 75 nm/min

- Refractive index 1.91

- Stress -180 ± 50 MPa

Upgrades

The Corial D350 PECVD system can be thoroughly customized with a wide range of features.

Additional gas inputs

Additional gas inputs (up to 8) for more complex process gas combinations

Light tower

![]()

The signal light tower provides an easy-to-view indicator of the system’s processing status

Laser interferometry

End point detection by laser interferometry to enhance process control through automated measurement of etch/deposition rate, etch depth and deposition thickness