Etching tools and deposition tools

Get the best Cost of Ownership with the most versatile, compact and reliable etch and deposition systems of the industry.

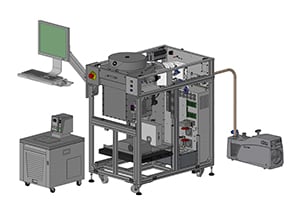

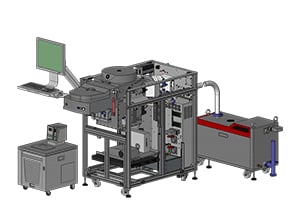

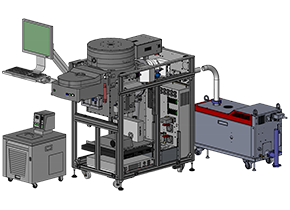

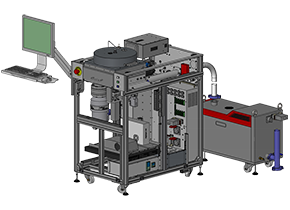

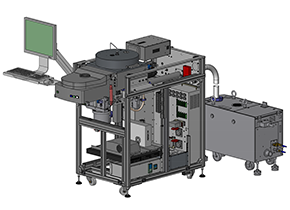

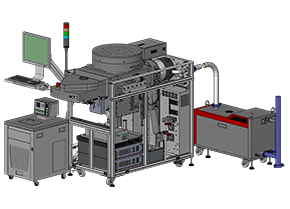

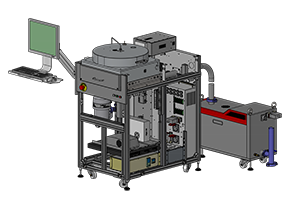

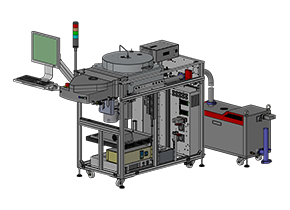

CORIAL 200 SERIES – Systems for R&D and Low Volume Production

Corial 200FA

- Deprocessing of dies and packaged dies

- Fast and clean etching of SiO2, Si3N4, and Polyimide layers

- Automated EPD to prevent TiN or metals etch

Corial 200S

- Simply to use, manually loaded RIE system

- Small wafer pieces up to full 200 mm wafer

- Si, silicon compounds, metals and polymers etch with fluorinated reactive gases

Corial 200R

- Easy to use system

- Stepped upgrades available

- For silicon-based compounds, metals and polymers etch

Corial 210RL

- Flexible solution for reactive ion etching

- Compatible with chlorinated chemistries

- Silicon, silicon compounds, polymers, III-V & II-VI compounds and metals etch

Corial 200I

- For single wafers over up to 200 mm, dies or packaged dies

- Fluorinated and oxygen based chemistries

- Silicon compounds and polymers etching

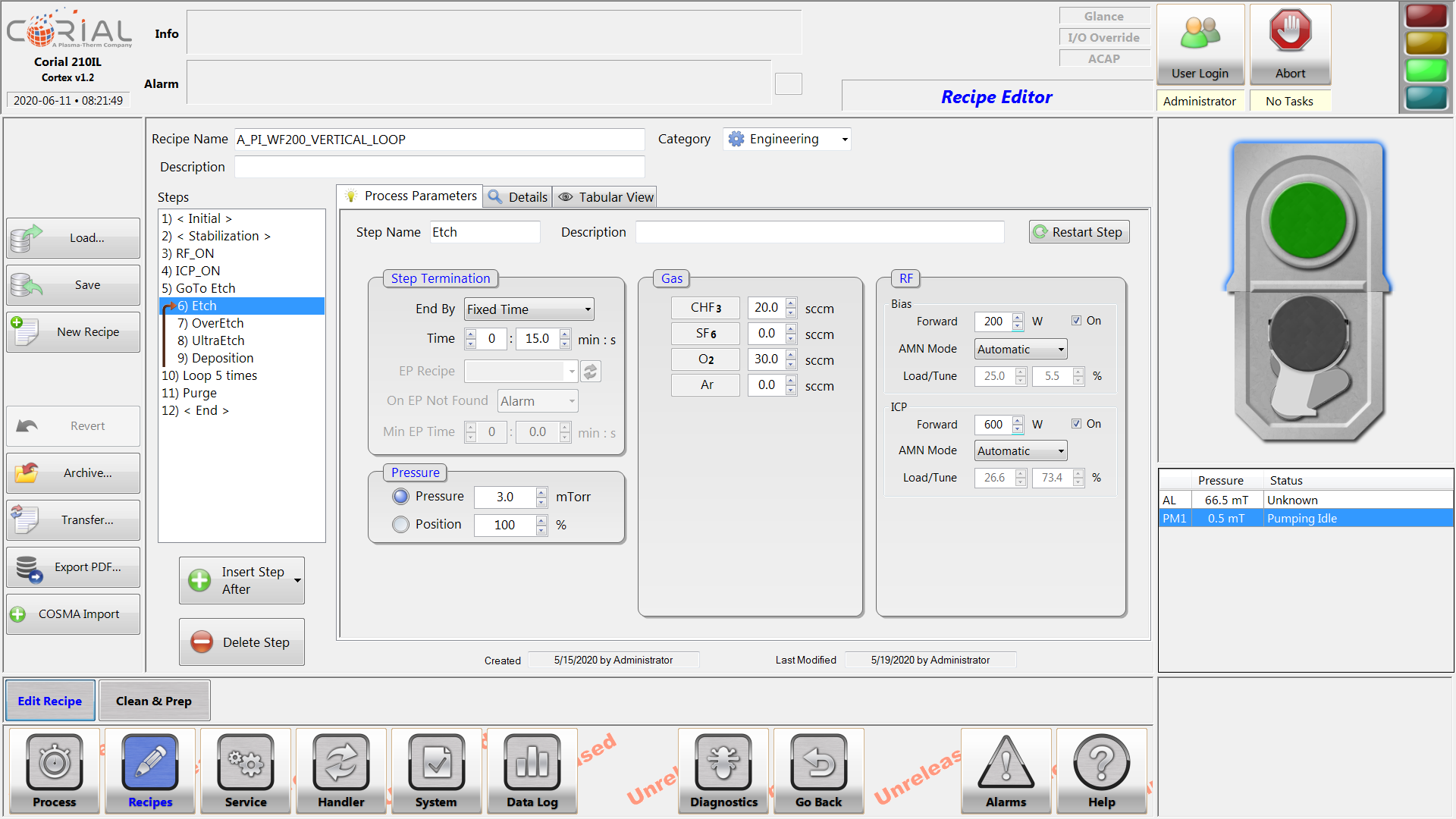

Corial 210IL

- Small wafer pieces up to full 200 mm wafer

- Support ICP, RIE, ALE and DRIE process recipes in the same reactor

- Fast etch rates and excellent uniformities

Corial 210D

- ICP-CVD system for R&D

- Low temperature deposition

- High quality SiO2, Si3N4, SiOCH, SiOF, SiC and aSi-H films

Corial D250

- PECVD system for low volume production

- In-situ plasma cleaning

- High quality SiO2, Si3N4, SiOCH, etc… films deposition

Corial D250L

- High throughput (load-lock)

- In-situ plasma cleaning

- High quality SSiOF, SiC and aSi-H films, etc…films deposition

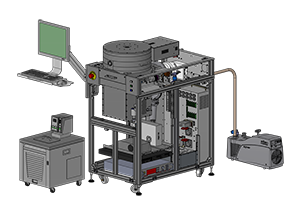

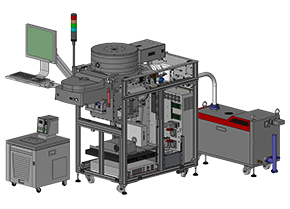

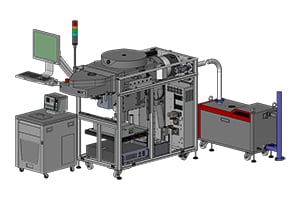

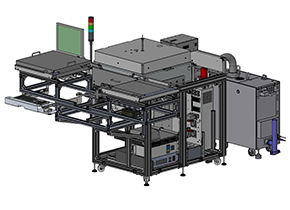

CORIAL 300 SERIES – Systems for 24/7 production environment

Corial 300S

- Large area reactor chromium etching for photomask fabrication

- From single wafer up to batch processing of 7 x 100 mm wafers

- Retractable liner for metal sputter etch

Corial 360RL

- Large area reactor chromium etching for photomask fabrication

- From single wafer up to batch processing of 7 x 100 mm wafers

- GaAs, GaP, InP, GaN and AlGaN etch

Corial 360IL

- System for 24/7 production environment

- Load-lock for batch up to 7 x 100mm wafers

- Fast etching rates for sapphire, oxides and polymers etch

Corial D350

- PECVD deposition system for 24/7 production environment

- Manual loading for up to 300 mm wafers

- High quality SiO2, Si3N4, SiOCH, SiOF, SiC and aSi-H films deposition

Corial D350L

- PECVD deposition system for 24/7 production environment

- Load-lock to increase throughput

- High quality SiO2, Si3N4, SiOCH, SiOF, SiC and aSi-H films deposition

CORIAL 500 SERIES – Very large area batch system

Corial D500

- Very large area PECVD deposition system

- High throughput: 104x2’’ ; 25x4’’ ; 9 x 6’’ or plates up to 500 mm x 500 mm

Software

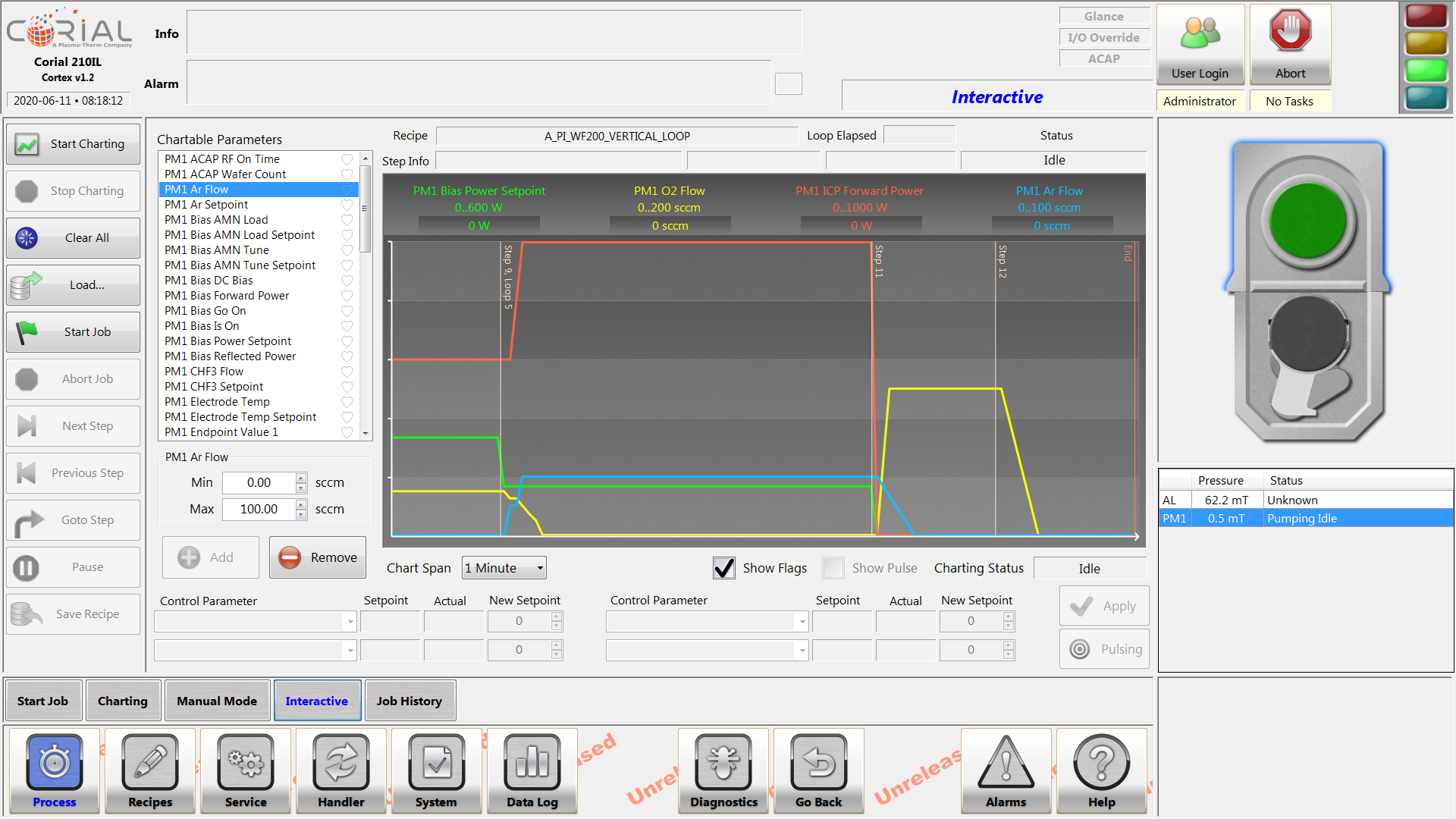

CORTEX®, for continuous wave recipes

- To develop processes, to operate, and to maintain CORIAL systems

- Simple to use GUI interface

- Multiple users access rights

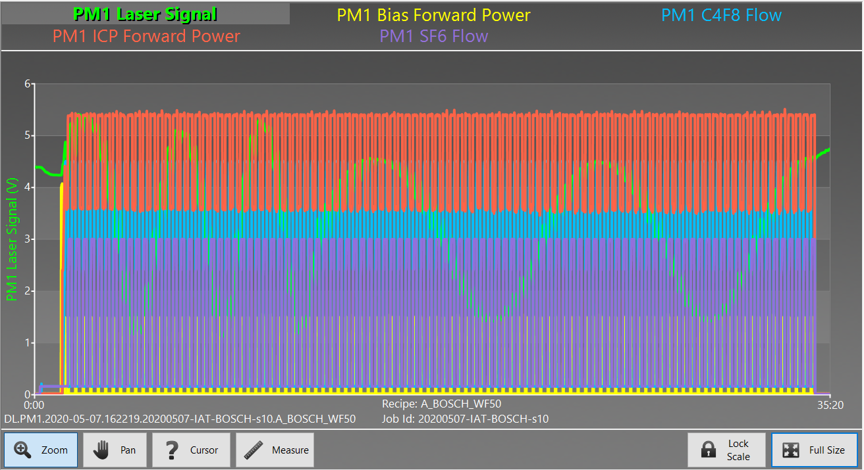

CORTEX® Pulse for time multiplexed recipes

- To control and pulse any process parameter, with a minimum pulsation period of 10 ms

- Control of DRIE Bosch, ALE and ALD processes on conventional systems

GLANCE™ RS, for reprocessing

- Display up to 4 parameters of a run

- Zoom on a specific step to fine tune the process

- Capability to compare 2 runs